Your One-Stop Partner in Mechanical Innovation.

Guided by expertise gained over 20 years of achieving success for clients, we practice with passion and strategic focus on the future.

🛠 Mechanical Services

We offer comprehensive mechanical engineering solutions that encompass design, manufacturing, hydraulic systems, documentation, and quality assurance. Our services are tailored to meet the needs of a wide range of industries, ensuring reliability, efficiency, and compliance with international standards.

Design & Engineering Services

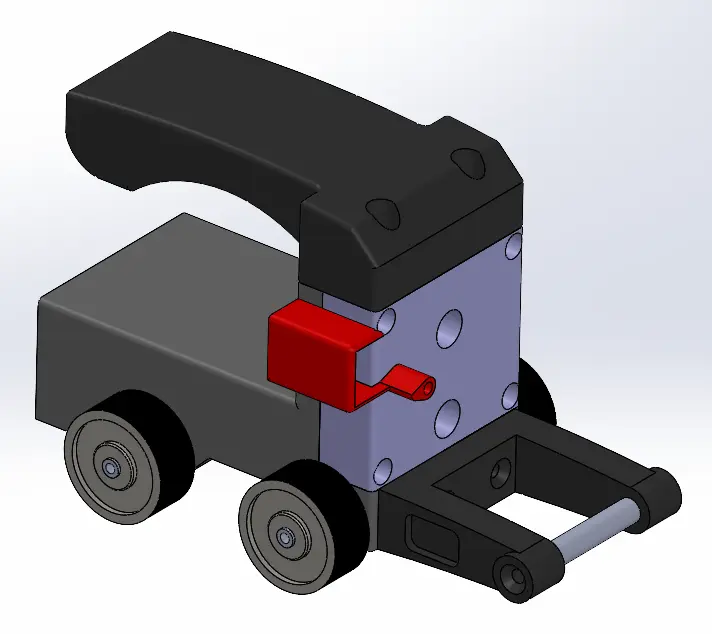

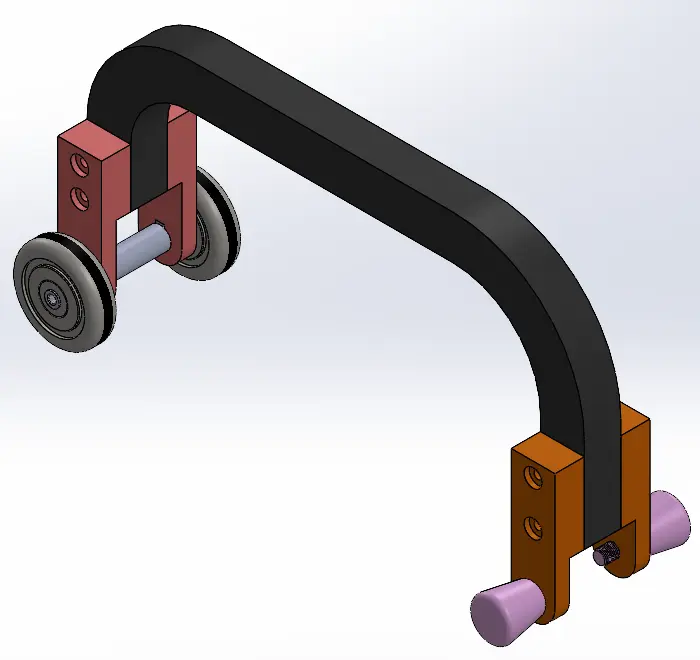

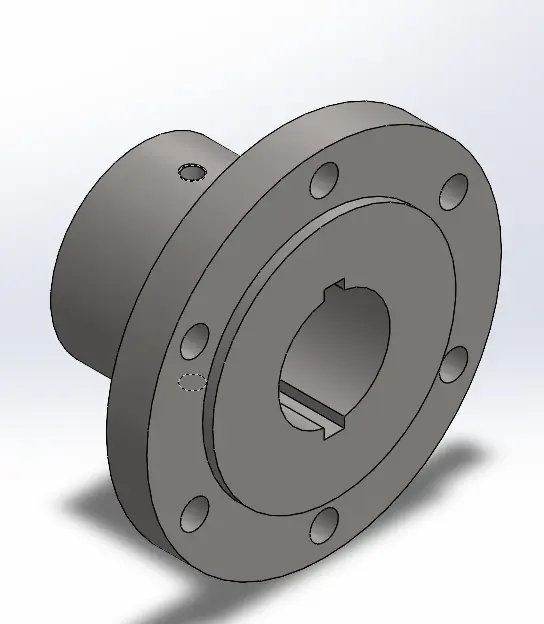

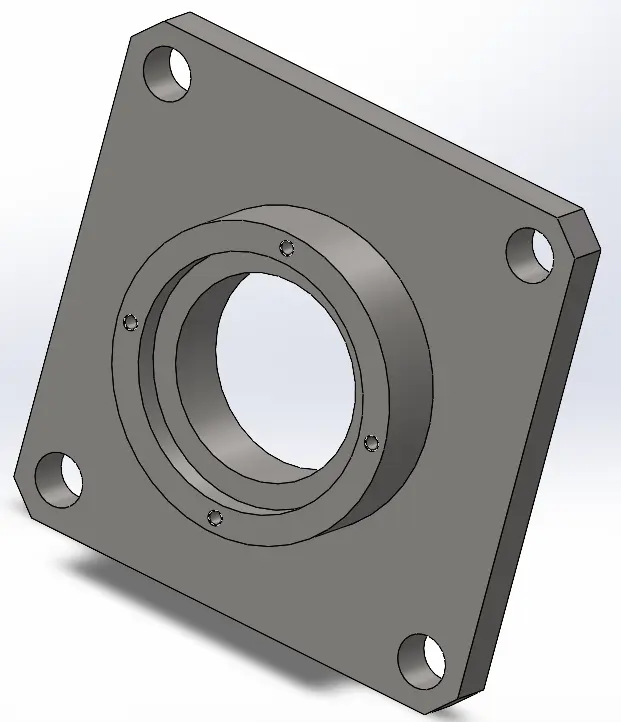

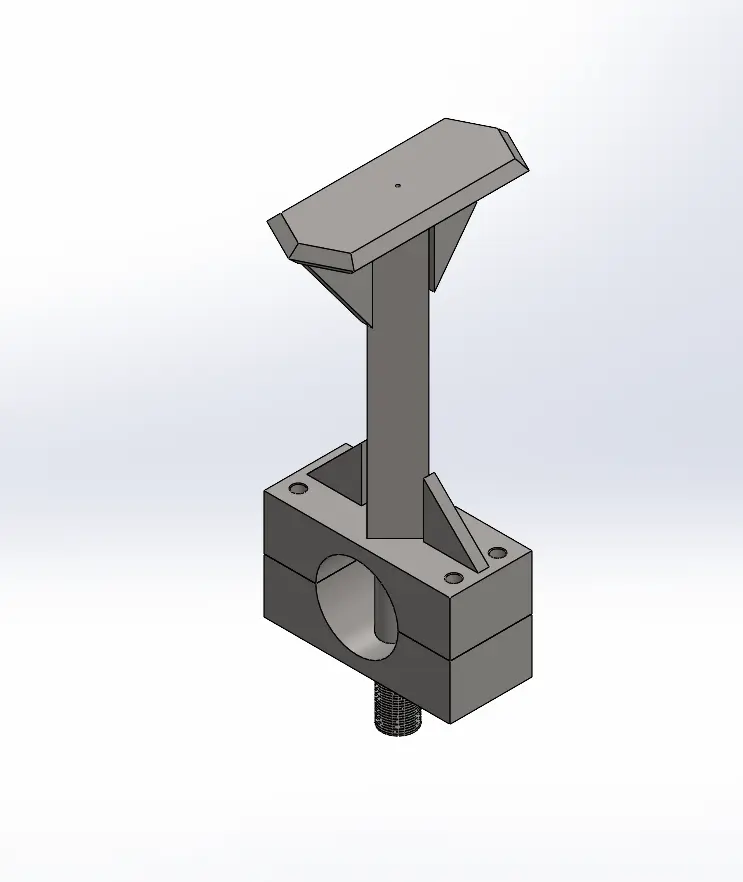

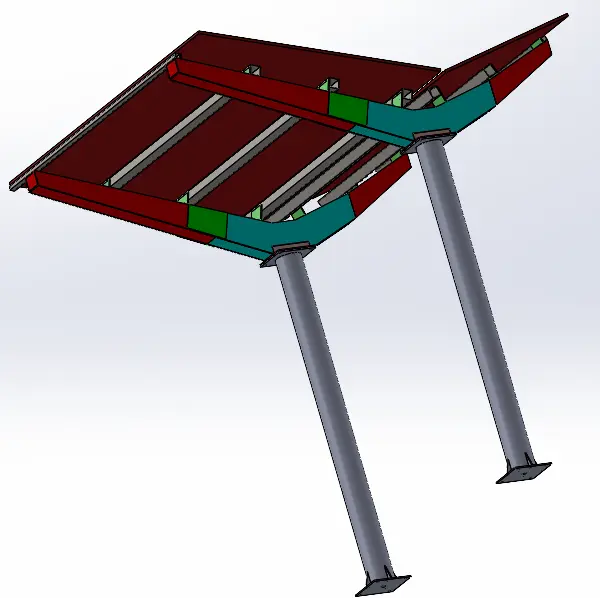

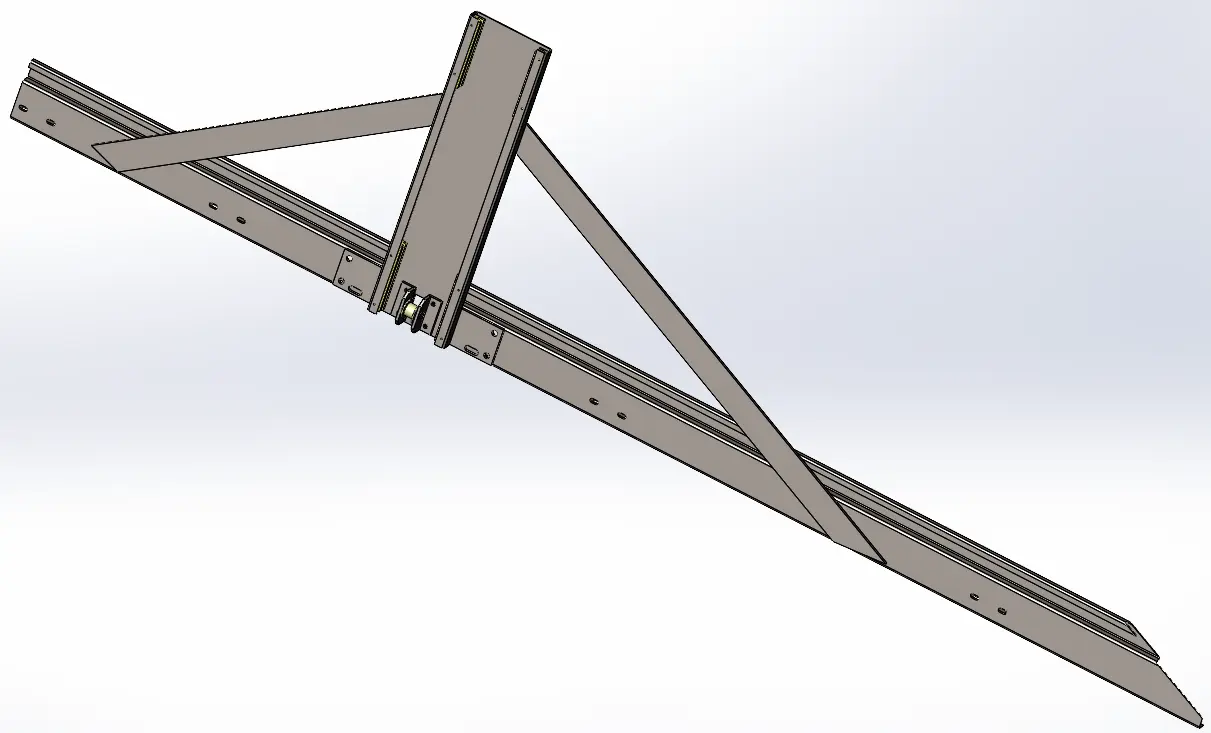

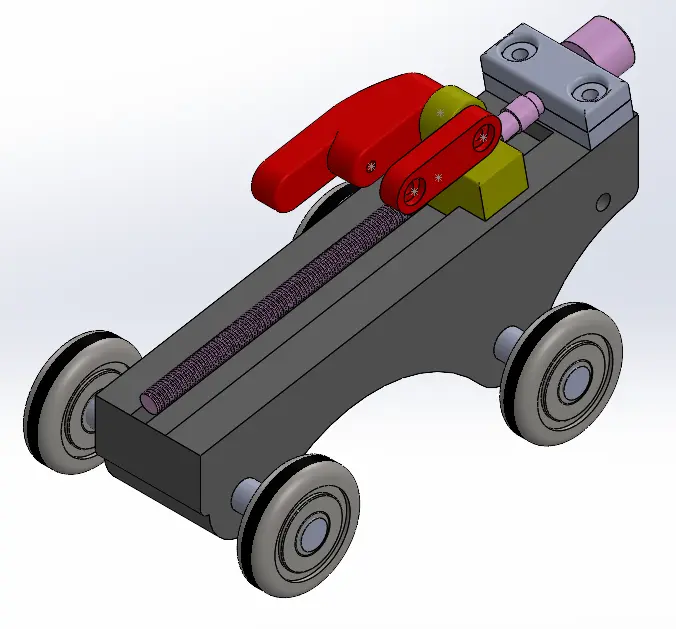

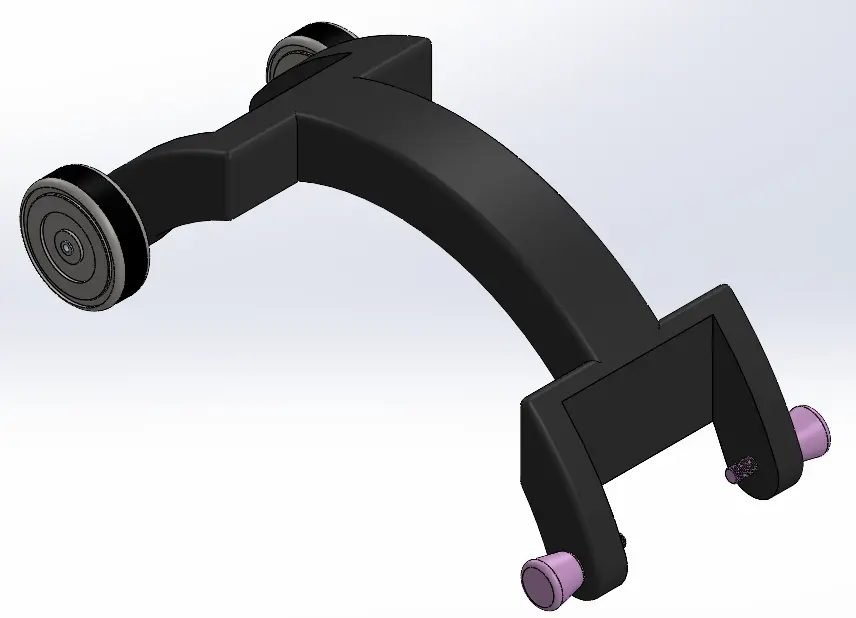

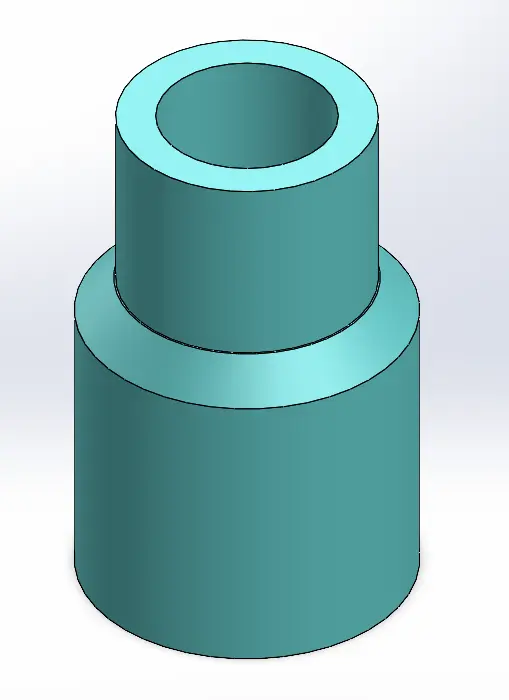

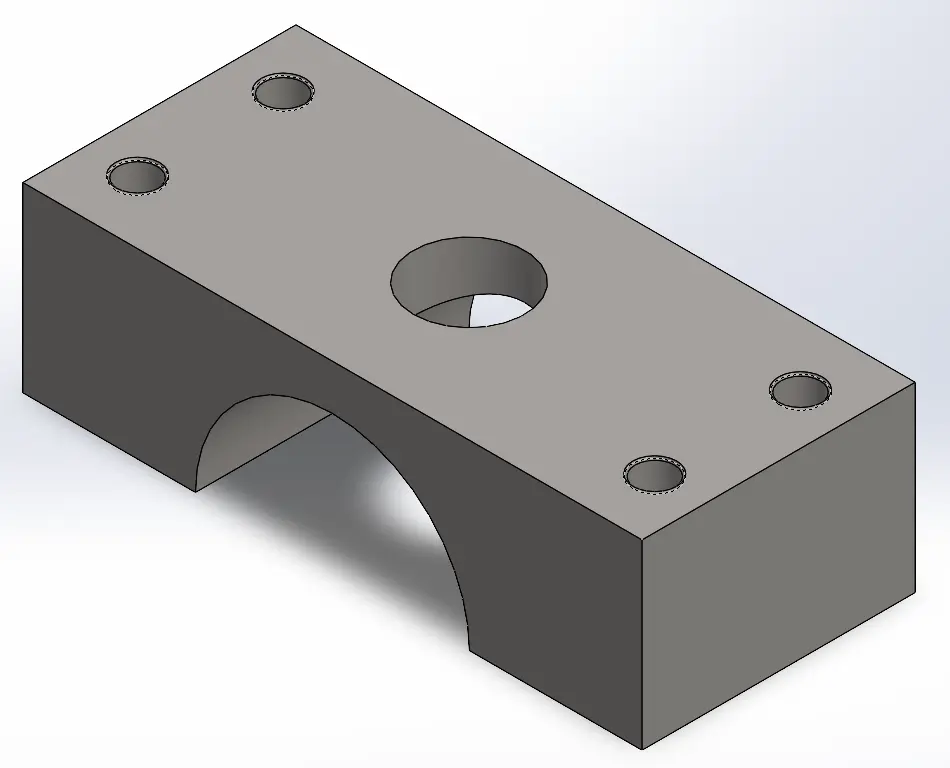

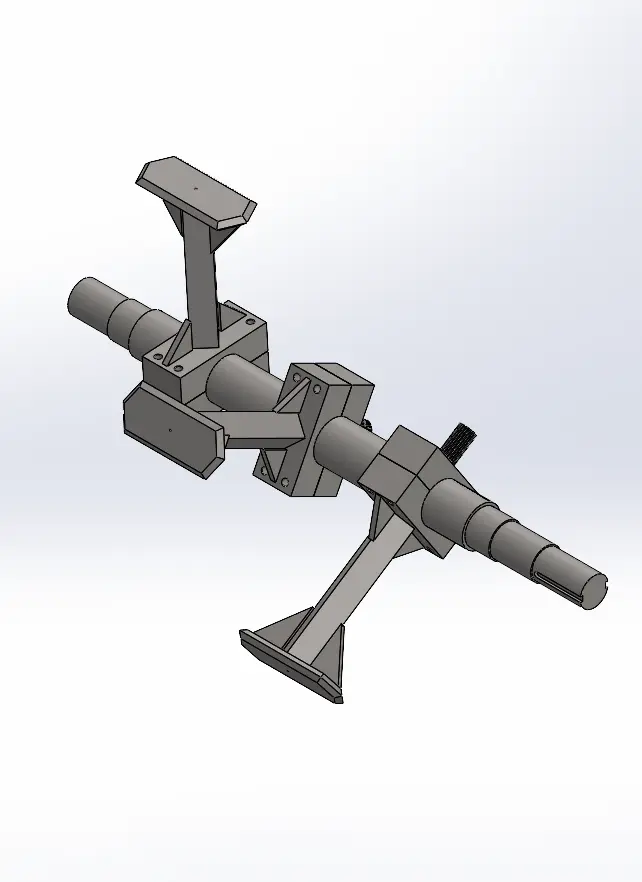

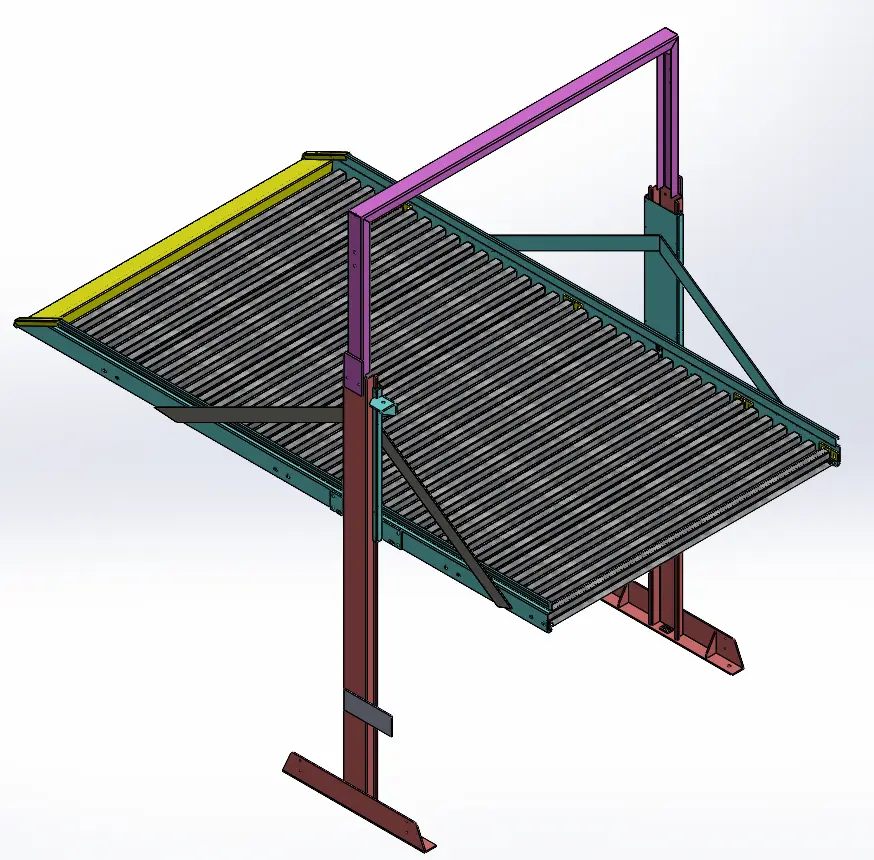

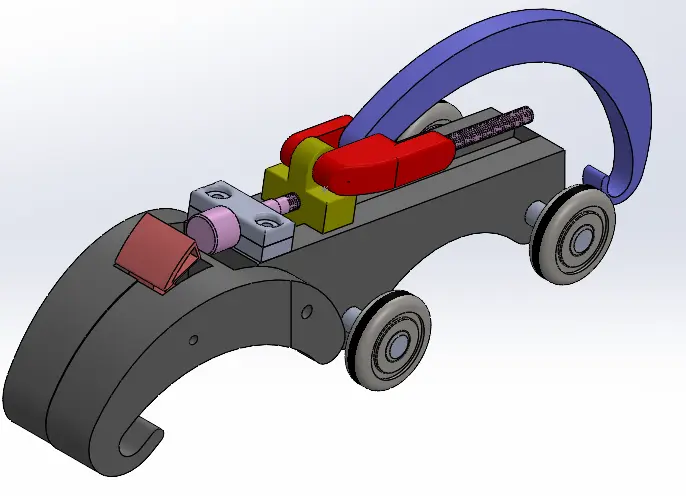

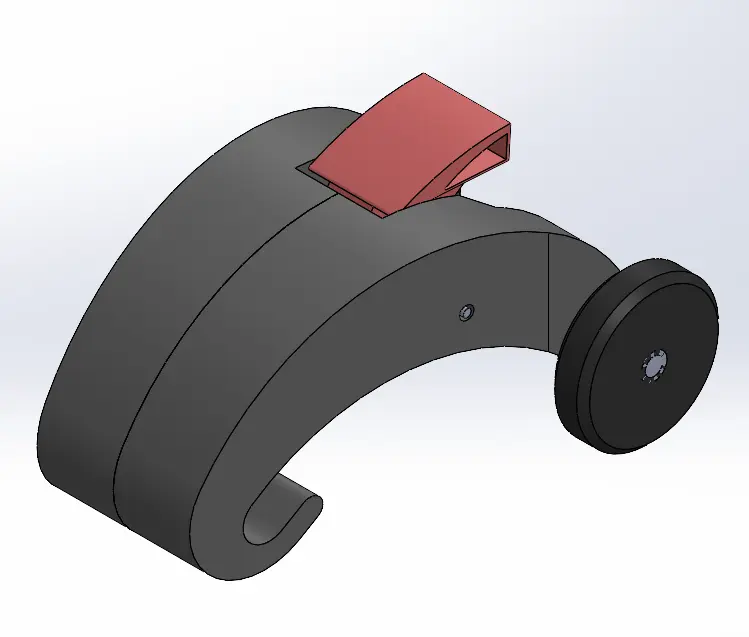

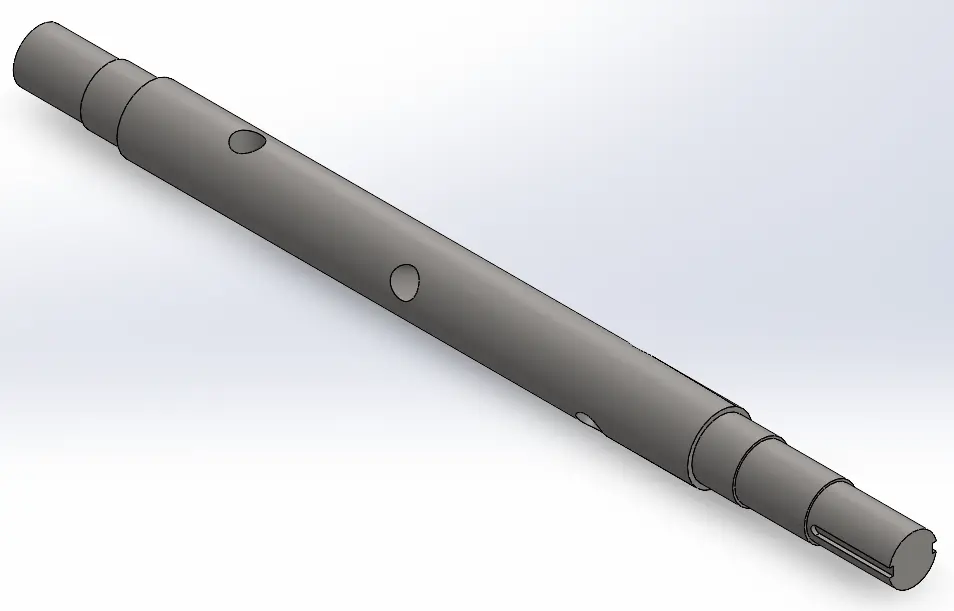

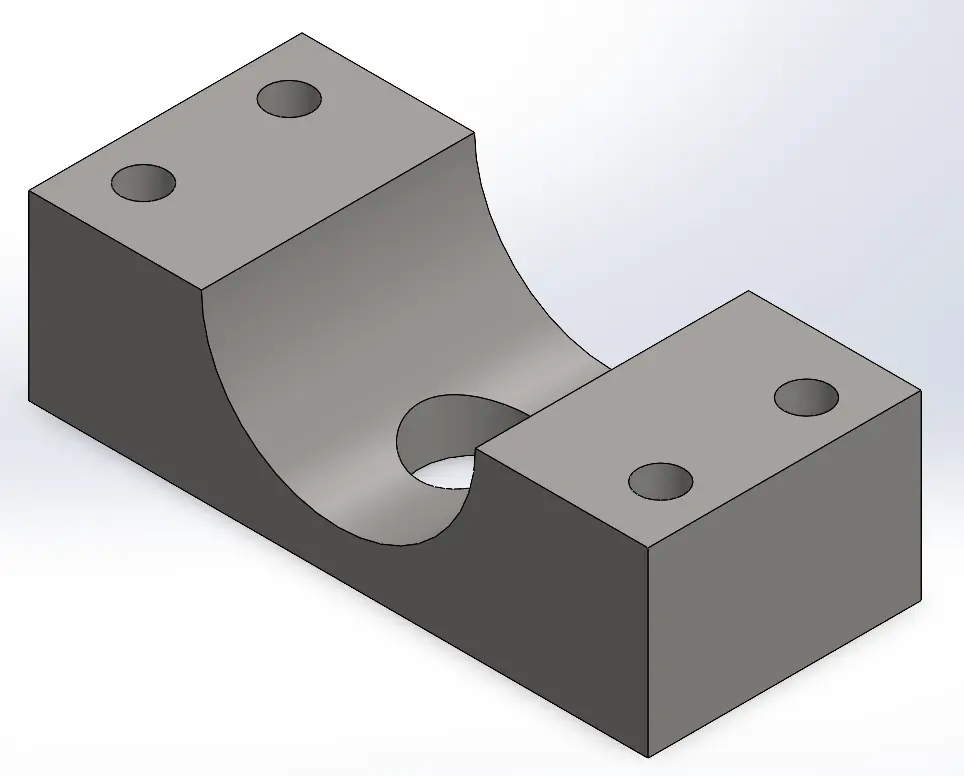

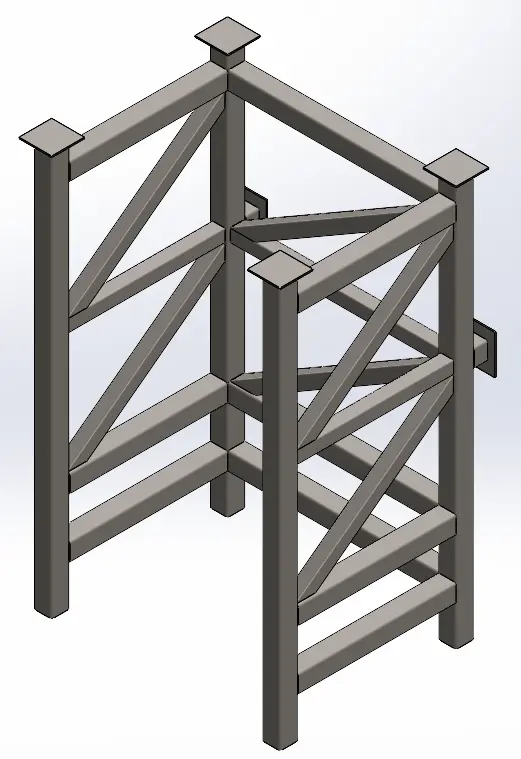

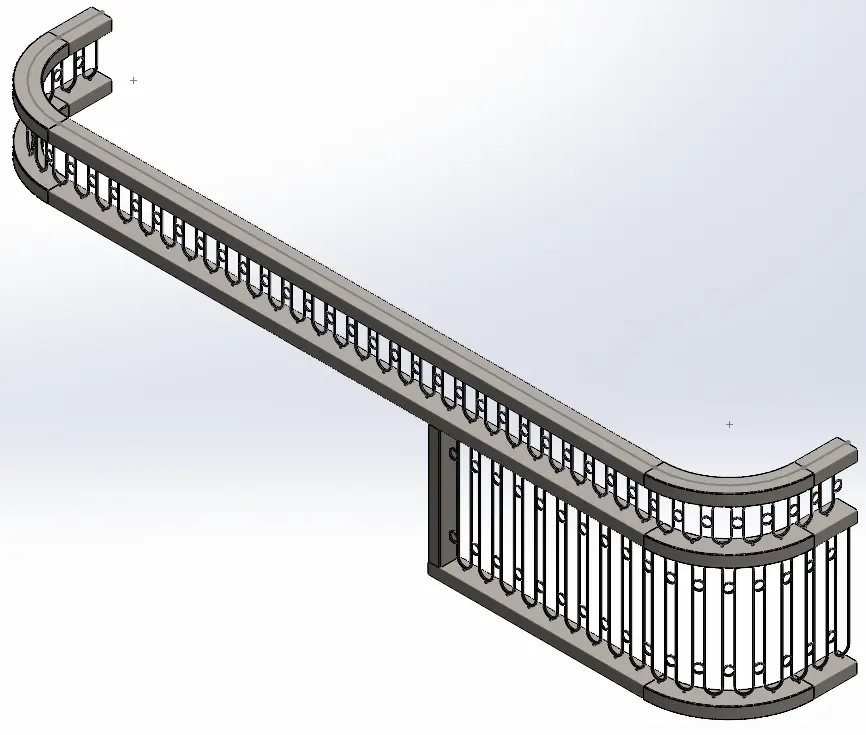

We provide end-to-end mechanical design and engineering solutions using advanced CAD/CAM tools and simulation software to ensure robust and cost-effective product development.

Services Include:

- Conceptual and detailed mechanical design

- 2D drafting and 3D modeling (SolidWorks, AutoCAD)

- Finite Element Analysis (FEA)

- Reverse engineering and re-design

- Material selection and design optimization

- Tolerance and fit analysis

- Prototype development support

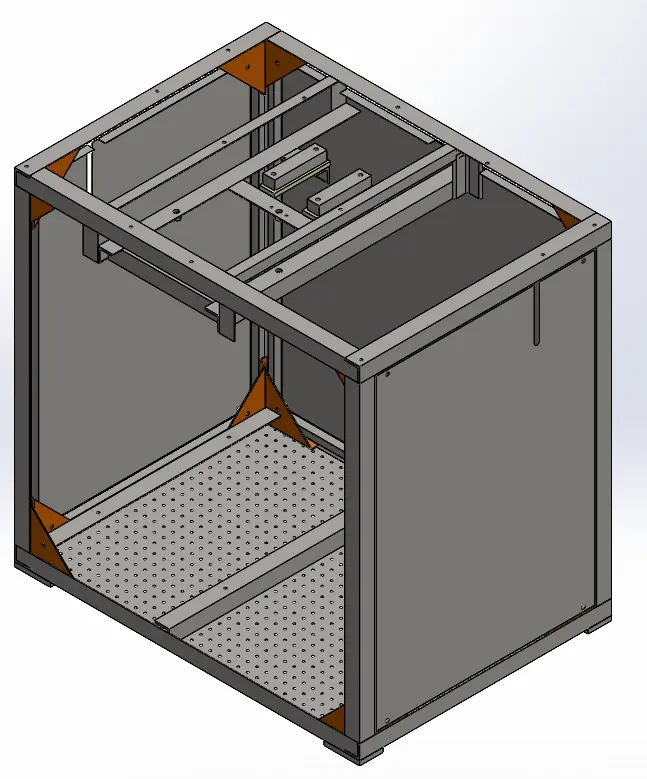

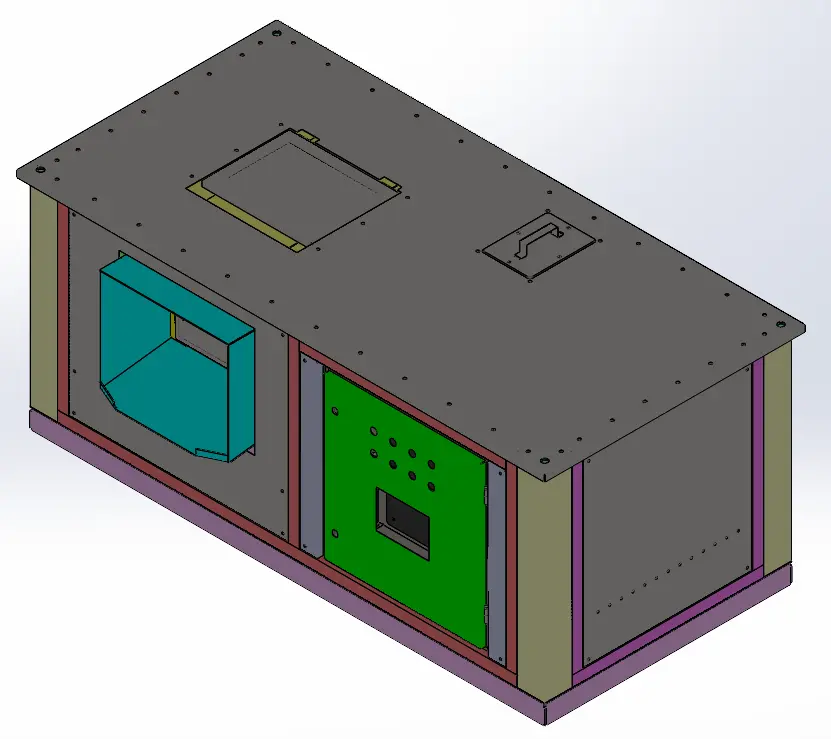

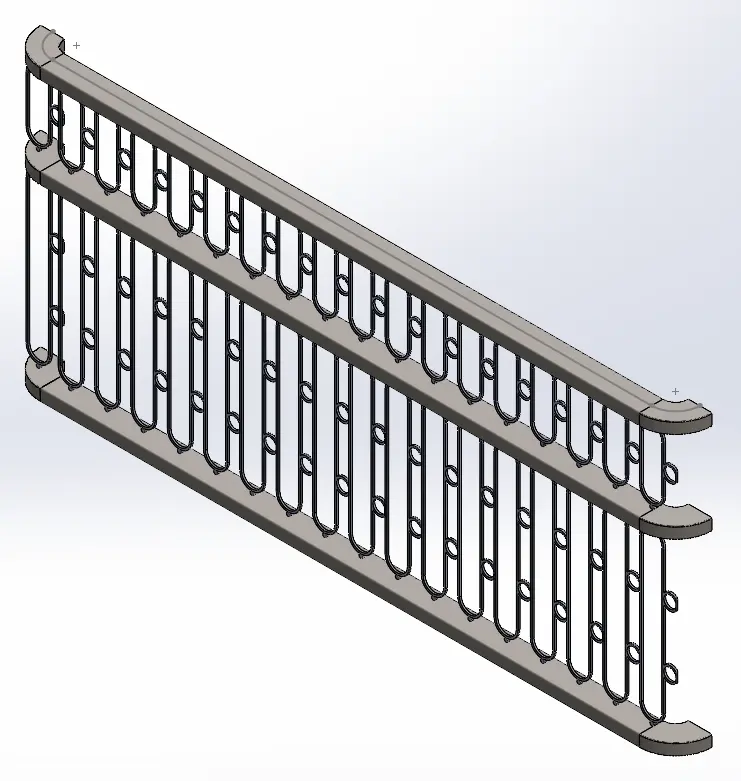

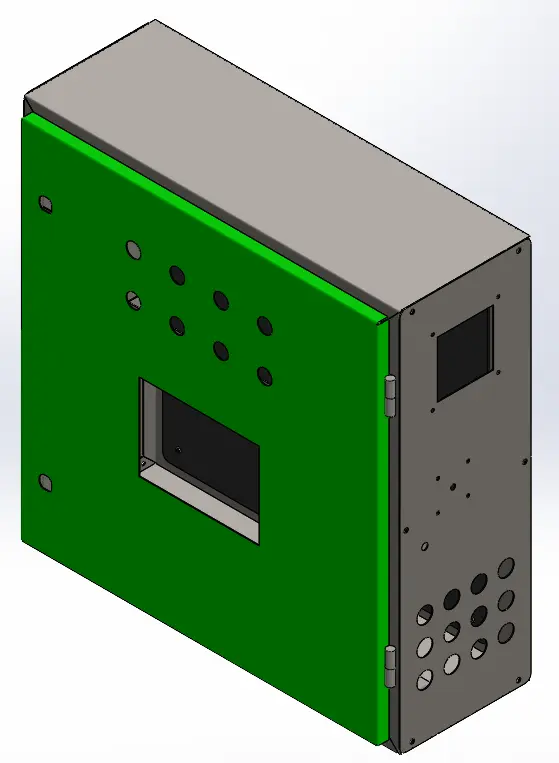

Sheet Metal Manufacturing

Precision sheet metal fabrication services for a wide range of industries including automotive, aerospace, electronics, and industrial applications.

Capabilities:

- CNC Laser Cutting, Plasma Cutting & Water Jet Cutting

- CNC Bending and Press Brake Forming

- Welding (MIG, TIG, Spot Welding)

- Punching, Notching, and Rolling

- Assembly and Riveting

- Finishing: Powder Coating, Plating, Anodizing

Materials Handled:

- Stainless Steel, Mild Steel, Aluminum, Copper, Brass, Galvanized Sheets

Deliverables:

- Custom Enclosures

- Control Panels

- Cabinets

- Brackets and Chassis

Sheet Metal Manufacturing process

Aim to meet the international standards

02

Bending Process

03

Welding Process

04

Coating Process

01

CNC Laser Cutting

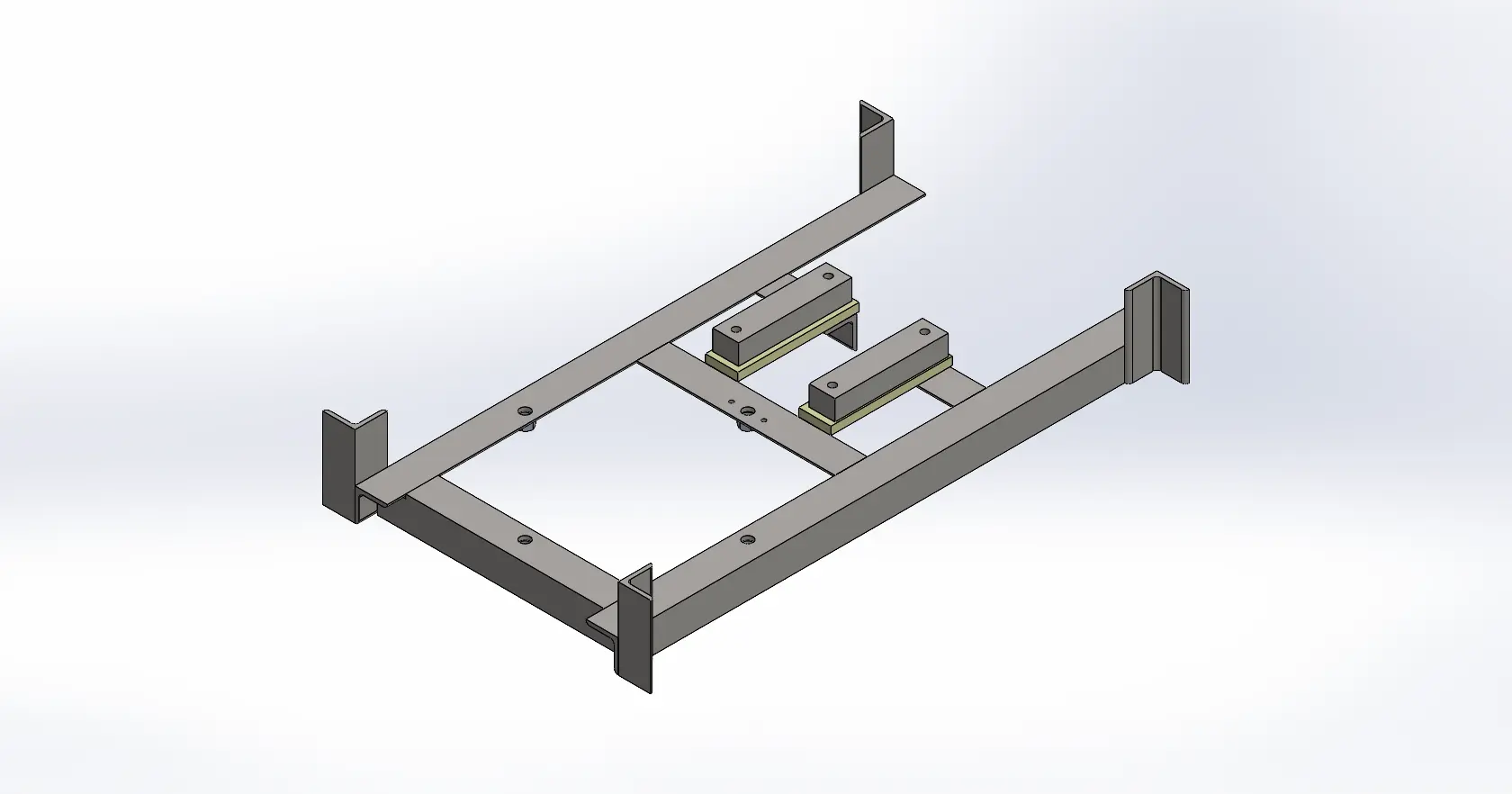

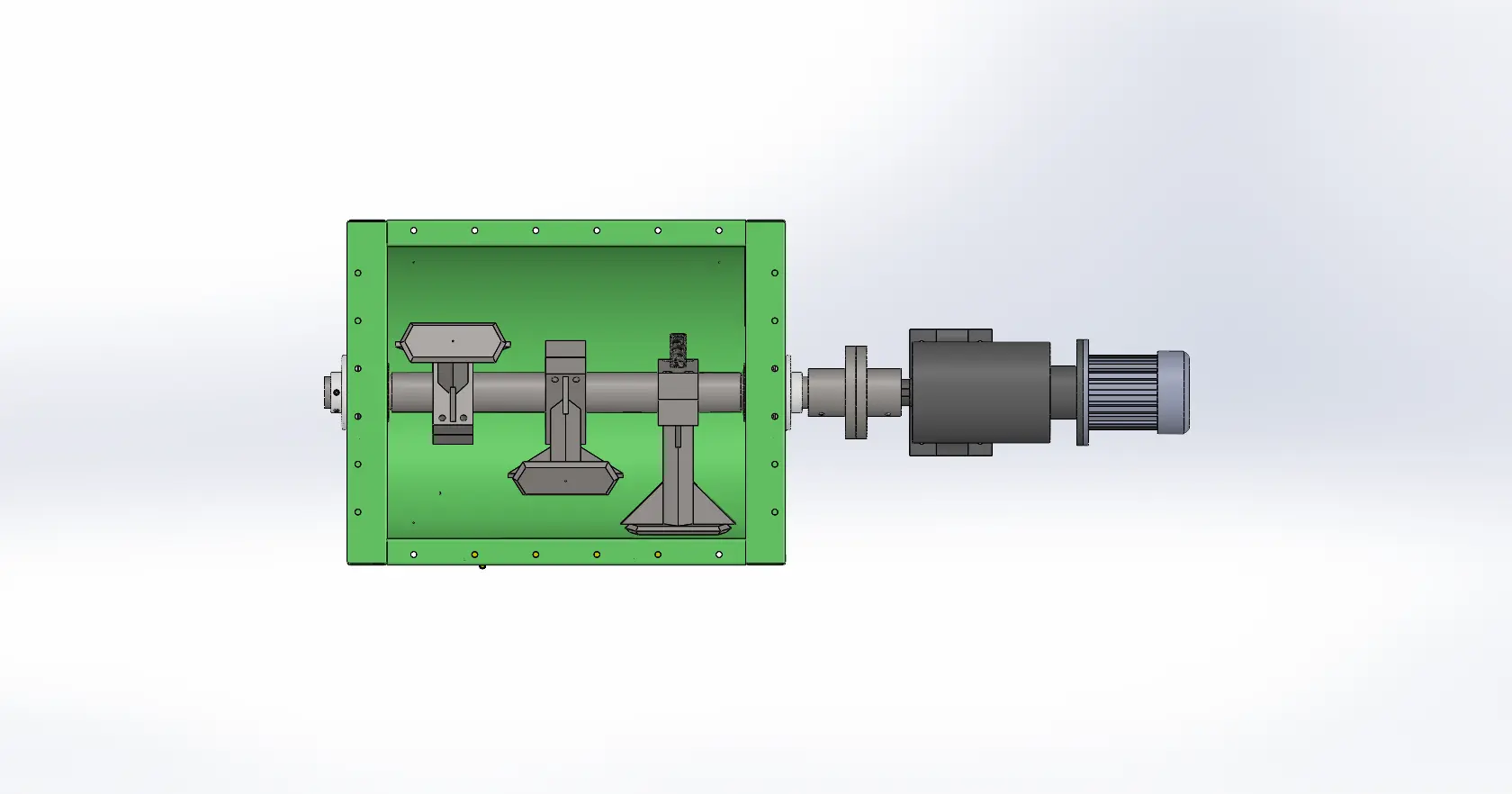

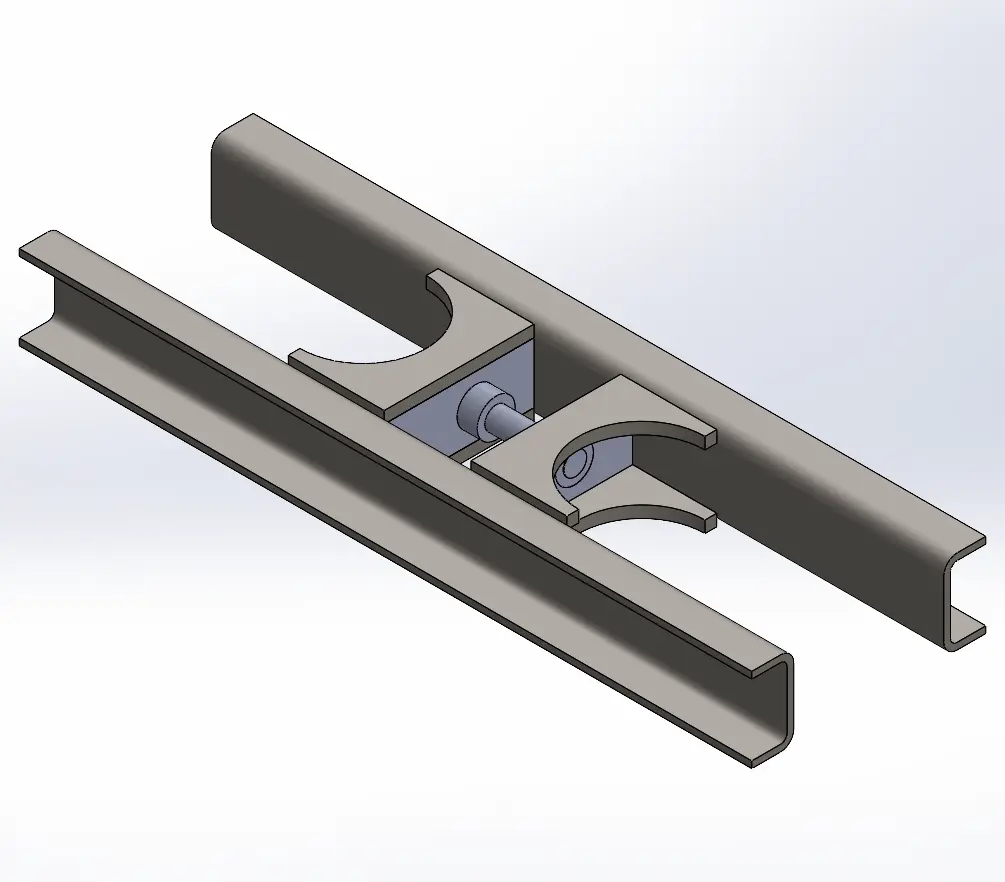

Machine Manufacturing & Assembly

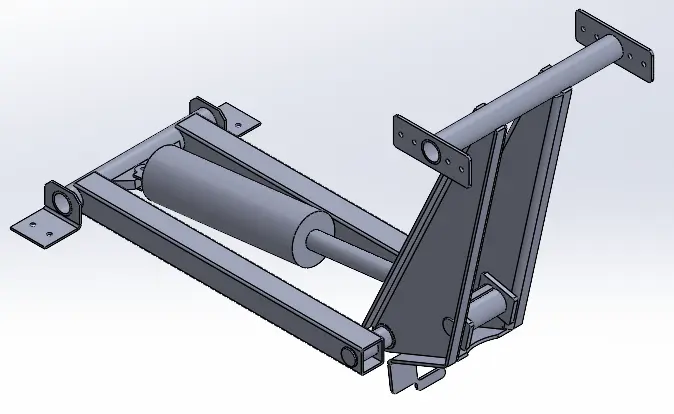

We manufacture high-precision machines and machine parts, with complete in-house capabilities for mechanical, electrical, and pneumatic integration.

Services Include:

- Custom machine design and fabrication

- CNC Machining – Milling, Turning, Drilling

- Jig and fixture design

- Assembly and testing of mechanical systems

- Integration of control systems (PLC, HMI, Pneumatics)

Industries Served:

- Automation

- Packaging

- Textile

- Food Processing

- Industrial Equipment

CNC & VMC Machining Services

we specialize in precision CNC (Computer Numerical Control) and VMC (Vertical Machining Center) machining services. Our advanced manufacturing capabilities are designed to deliver high-quality components with tight tolerances, exceptional surface finishes, and reliable repeatability across a wide range of materials.

Whether you're in the aerospace, automotive, medical, defense, or industrial equipment sector, our state-of-the-art CNC and VMC machines ensure efficient production, reduced lead times, and outstanding performance for every part we produce.

🔧 CNC Machining Services

CNC machining is a manufacturing process where pre-programmed computer software controls the movement of factory tools and machinery. This process allows for the production of complex parts with unmatched accuracy and repeatability.

Our CNC machining capabilities include:

- 3-axis, 4-axis, and 5-axis CNC milling

- CNC turning and lathe work

- Multi-material machining: Steel, stainless steel, aluminum, brass, copper, plastics, and exotic alloys

- Precision tolerances: Up to ±0.005 mm

- Custom part production: Prototypes, short runs, and high-volume batches

🛠️ VMC (Vertical Machining Center) Services

VMC machining uses a vertically oriented spindle, ideal for creating complex shapes and high-precision components. These machines are perfect for operations like face milling, contouring, slotting, drilling, and tapping.

Our VMC machining features:

- High-speed, computer-controlled vertical milling

- Suitable for 2D and 3D complex geometries

- Advanced CAD/CAM integration for efficient workflows

- Rigid machine structures for better accuracy and surface finish

- Fast tool changes and reduced cycle times

✅ Quality & Inspection

we ensure every part meets the highest quality standards. Our quality control process includes:

- In-process and final inspections

- CMM (Coordinate Measuring Machine) testing

- Surface roughness testing

- Dimensional accuracy verification

Technical Documentation & Standards Compliance

We provide professionally written and structured documentation tailored to global standards, ensuring regulatory compliance and operational clarity.

Documentation Includes:

- Engineering drawings

- Bill of Materials (BOM)

- Process Flow Diagrams (PFD) & Piping and Instrumentation Diagrams (P&ID)

- Operation & Maintenance Manuals (O&M)

- Assembly Instructions

- Risk Assessments and Safety Guidelines

Standards Followed:

-

IS

- ASME, ASTM

- DIN, ANSI, IEC

- CE Marking Requirements

Quality Assurance & Control

Quality is integral to our process. We implement stringent quality assurance and control protocols at every stage of production and delivery.

QA/QC Highlights:

- Incoming material inspection

- In-process inspection and control

- Final inspection reports (FIR)

- Dimensional inspection using CMM and other precision instruments

- Surface finish and hardness testing

- Approved quality processes

- Factory Acceptance test

- Material Test Certificate (MTC)

- Surface preparation Test Report

Certifications & Traceability:

- Full material traceability

- Certification of conformity

- Test certificates (Mill Test, NDT reports)

Why Choose Us?

- Cutting-edge technology & machinery

- Highly skilled engineering & technician teams

- On-time delivery and cost-effective solutions

- Adherence to global quality and documentation standards

- Trusted by industry leaders across sectors